Transforming Manufacturing with Advanced Casting Techniques

The manufacturing industry has experienced a remarkable transformation over the past decades, driven by the need for precision, efficiency, and durable components. Among the technologies that have shaped modern production, aluminium high pressure die casting stands out as a process that enables manufacturers to produce complex, lightweight, and high-strength components at scale. Industries ranging from automotive to aerospace, electronics, and industrial machinery increasingly rely on this method to meet demanding design and performance standards. By partnering with experienced die casting providers, companies can access high-quality parts while optimizing production efficiency and cost-effectiveness.

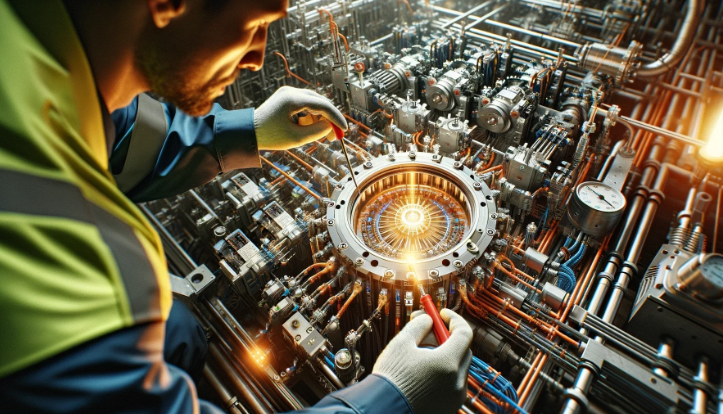

Understanding Aluminium High Pressure Die Casting

Aluminium high pressure die casting is a process in which molten aluminum is injected into a steel mold, known as a die, under very high pressure. This technique allows the production of components with intricate geometries, consistent dimensions, and excellent surface finishes. Unlike traditional casting methods that rely on gravity, high pressure die casting ensures uniform filling, minimizes material waste, and significantly reduces production time.

The process begins with die design, carefully tailored to meet the specifications of the intended part. Once the die is ready, molten aluminum is injected at high pressure into the mold cavity. After solidification, the die opens, and the finished component is ejected. Additional finishing processes such as trimming, machining, or surface treatment may be applied to meet precise functional or aesthetic requirements.

Advantages of Aluminium High Pressure Die Casting

The use of aluminium high pressure die casting offers numerous benefits that make it a preferred choice for modern manufacturers.

Precision and Consistency

High pressure die casting enables the production of components with tight tolerances and consistent quality. This precision is crucial for applications in automotive, aerospace, and electronics industries, where even minor deviations can impact performance and safety.

Ability to Produce Complex Designs

One of the most significant advantages of high pressure die casting is its capacity to produce intricate shapes and internal cavities. Components aluminium high pressure die casting with thin walls, curves, and undercuts can be manufactured efficiently, allowing engineers to innovate in both design and functionality.

Lightweight and Strong Components

Aluminium provides a high strength-to-weight ratio, making it ideal for applications where durability is required without adding excess weight. High pressure die cast parts are robust, able to withstand mechanical stress and extreme operating conditions, while contributing to overall weight reduction in products such as vehicles and aircraft.

Cost Efficiency

Despite the initial investment in dies and machinery, aluminium high pressure die casting reduces labor costs, minimizes material waste, and supports high-volume production. Over time, manufacturers benefit from lower per-unit costs while maintaining consistent quality across large production runs.

Superior Surface Finish

The process produces components with smooth surfaces, often requiring minimal finishing. This not only reduces post-production costs but also ensures that the components are suitable for both functional and decorative applications.

Applications Across Industries

Aluminium high pressure die casting is widely used across multiple sectors, offering versatility and reliability.

Automotive Industry

In the automotive sector, die cast components are used for engine blocks, transmission housings, suspension parts, and structural elements. The lightweight properties of aluminum improve fuel efficiency, while the strength and precision ensure components can withstand high stress and temperature variations.

Aerospace

Aerospace manufacturers rely on aluminium high pressure die casting to produce structural supports, brackets, and housings. The combination of light weight, high strength, and dimensional accuracy allows aircraft components to meet stringent safety and performance standards.

Electronics

Electronics applications benefit from die cast aluminum components such as housings, heat sinks, and connectors. Aluminium’s excellent thermal conductivity and shielding properties protect sensitive electronic components while ensuring operational efficiency.

Industrial Machinery

Industrial machinery often requires components that are precise, durable, and capable of enduring heavy loads. Aluminium high pressure die casting provides gears, housings, pumps, and other parts that maintain reliability and dimensional accuracy even under demanding operational conditions.

Consumer Products

From home appliances to recreational equipment, die cast aluminum components enhance product durability, aesthetic appeal, and performance. The ability to produce complex shapes and achieve high-quality surface finishes adds value to the final product.

Quality Control and Standards

A critical aspect of successful aluminium high pressure die casting is rigorous quality control. Leading manufacturers implement advanced inspection techniques, including coordinate measuring machines (CMM), X-ray testing, and material strength analysis. These measures ensure components meet stringent dimensional and mechanical requirements, reduce defects, and maintain consistency across production batches.

See also: Understanding Infusion Methods: Gravity vs Pump

Innovations in Aluminium High Pressure Die Casting

The aluminium die casting industry continues to evolve with innovations that improve efficiency, quality, and design possibilities. Key developments include:

- Multi-axis die casting machines: These allow the production of complex parts with fewer setups, improving efficiency.

- Advanced aluminum alloys: New formulations enhance strength, corrosion resistance, and reduce weight.

- Automation and robotics: Automated trimming, handling, and finishing reduce human error and increase production speed.

- Simulation and design software: Advanced tools optimize die design, material flow, and cooling, reducing defects and improving overall quality.

Sustainability in Aluminium High Pressure Die Casting

Sustainability has become an essential focus in manufacturing. Aluminium is fully recyclable without losing quality, and high pressure die casting reduces material waste through optimized die designs. Energy-efficient production techniques and precise process control minimize environmental impact, allowing companies to meet sustainability goals while maintaining production efficiency.

Future Outlook

The demand for aluminium high pressure die casting continues to grow as industries seek lightweight, high-strength, and precision-engineered components. Ongoing advancements in automation, alloy development, and process optimization will enhance production efficiency and component quality.

Aluminium high pressure die casting remains a cornerstone of modern manufacturing, offering unmatched precision, versatility, and cost-effectiveness. Companies that leverage the expertise of experienced die casting providers can produce durable, high-performance components efficiently, supporting innovation and growth across automotive, aerospace, electronics, and industrial sectors.

By combining advanced technology, skilled engineering, and rigorous quality control, aluminium high pressure die casting ensures that manufacturers meet the evolving demands of global industries while achieving operational efficiency and sustainability.